Renthal - Factory Visit

Recently before the trip to Eurobike we managed to make a visit to the Renthal factory in the UK and see how they make stuff. It is a kids play ground if you like machines and metal and making stuff. You get a real sense that what they make is done 100% hands on and with care, it is not just a computer knocking out bits of metal controlled by someone who doesn’t even know what they are for… Here we collected a selection of photos that show what we found there.

Renthal Factory Pictures

Sprockets from motorbikes.

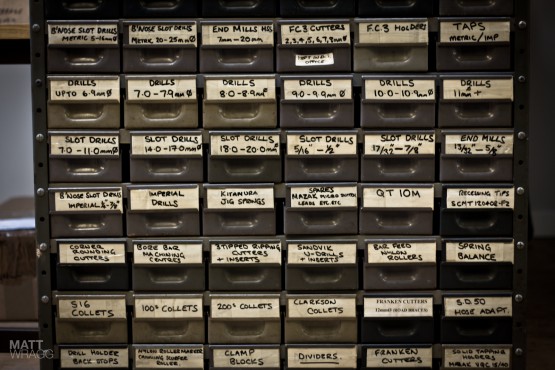

How well-ordered do you want to be? Drill bits for machining.

These are the hydraulic lines at the back of their machine for testing bar stiffness.

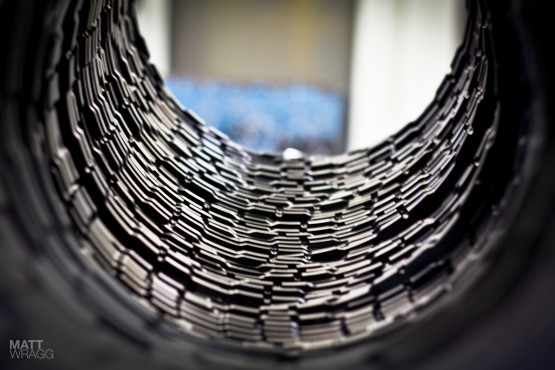

Metal shavings left after the CNCing process

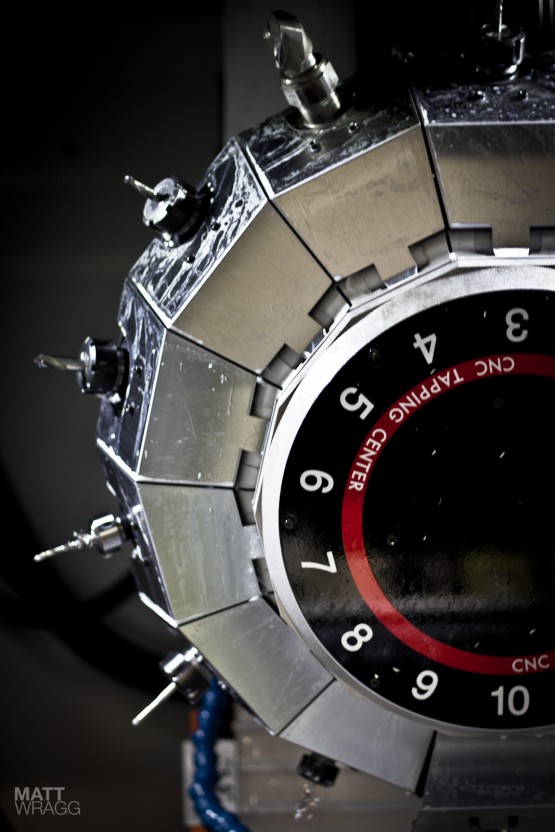

Heads for the CNC machine, not a doomsday device.

More drillheads for CNCing.

More metal left after CNCing - there’s a lot of it!

Large sprockets for motos are made in two stages - a light ali inner and a tough, steel outer. These are the outers waiting for their inners.

Another angle of those sprocket outers.

The blank piece of metal that will become a sprocket outer.

The plasma cutter that cuts those discs out of sheet metal.

No idea what this was, it just amused me that they’d jammed a hammer in there.

Spare motorbike chain-links.